The “head” of the skeleton represents the difficulty or influence, which is generally shown on the right side. It acquires its name for its appearance shape which matches the side aspect of the skeleton of a fish.

Sometimes, it can also be desirable to analyze what can go wrong – preventing future difficulties. It helps to recognize, analyze and fix quality issues. It serves to reflect the potential causes in line to obtain the root cause of a particular query. Furthermore, it supports to export your file in multiple formats, such as Graphics, PDF, HTML, Visio and more.The Fishbone diagram is 1 of the seven quality circles (QC). Except that, the substantial fishbone diagram symbols and templates make your creation easier and easier. EdrawMax's built-in feature can hide sensitive data and prevent unauthorized access. Our online fishbone diagram maker keeps your data safe and sound. Use EdrawMax online to create your fishbone diagram without efforts, just grab a fishbone diagram template or choose one fishbone diagram template from EdrawMax Template Gallery and keep customization as your preference, and your fishbone diagram is ready. This showcases how every subdivision of a certain category is looked into to determine how it contributes to a final cause.ĮdrawMax Online not just a fishbone diagram maker. These have further sub-branches such as measurement pertaining to accuracy, sampling, and bias whereas method would comprise of a recipe or operating process. This is in context to the Ms such as machine, measurement, method and materials.

In the context of manufacturing, the classic fishbone diagram example holds true every time. The different causes in each category are then showcased as sub-branches.Įxample 5: Manufacturing Fishbone Diagram Here low quality or inefficient service can be a concern that is discussed in the light of probable causes such as physical evidence, place, service, people, production and quality, price, process, and production. One can also see a fishbone diagram example in the context of problems that arise in the service industry. For each branch or category there are sub-branches that are highlighted which are constraints that contribute to hindering output.Įxample 4: Service Industry Fishbone Diagram For instance, if the low-quality output is a concern, the different branches or probable causes are first identified under broad categories such as management, raw materials, technology, working conditions, machine and workers. There are widespread uses of cause and effect diagram example in businesses. For instance, the five whys can be illustrated with a funny image in order for viewers or participants to understand the visuals easily. It helps especially to draw the attention of children or young minds when a problem solving is being attempted with visual aids in class. The fix processes comprise 6 Ms that stands for material, measurement, Mother Nature or milieu, manpower, and method.Īny problem and its probable causes can be showcased with a funny cause and effect diagram example as well.

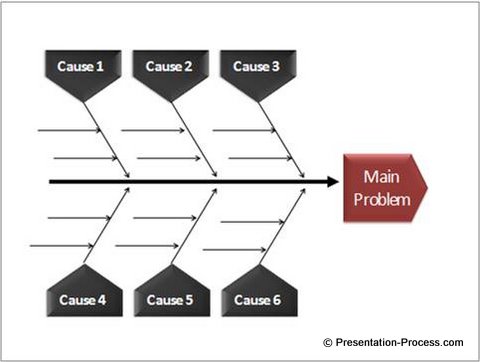

It is one of the quality tools that was invented to understand how a problem occurs and the effects of the same. No matter what they are called, these diagrams act as analytical tools to look at the different causes that lead to a certain effect. Such illustrations can be reverse fishbone type as well. The short form for cause and effect diagram is CEDAC which can be done with cards as well. These can also be called cause enumeration or process fishbone diagrams or showcasing time-delays. Fishbone diagrams are also known as cause and effect diagrams or Ishikawa diagrams.

0 kommentar(er)

0 kommentar(er)